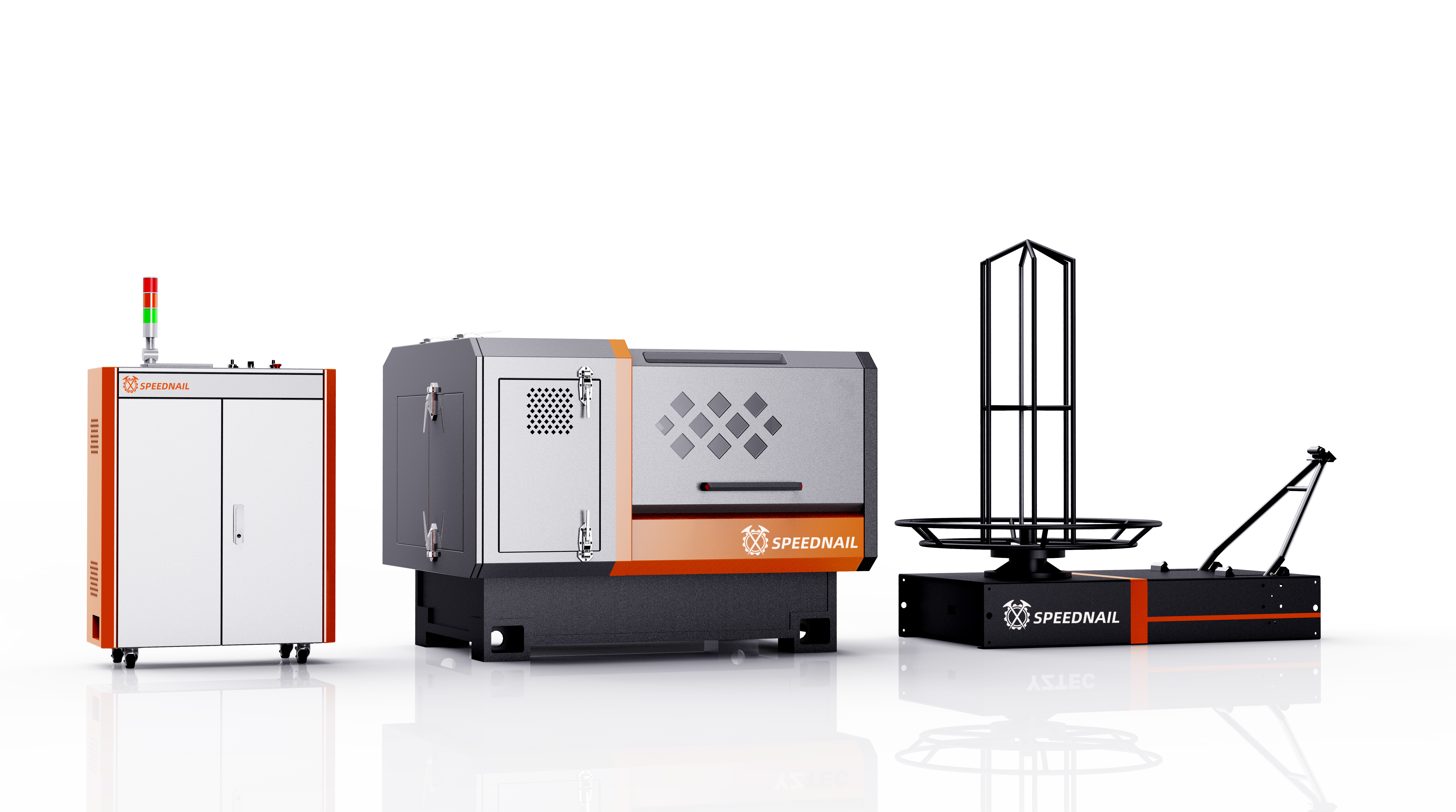

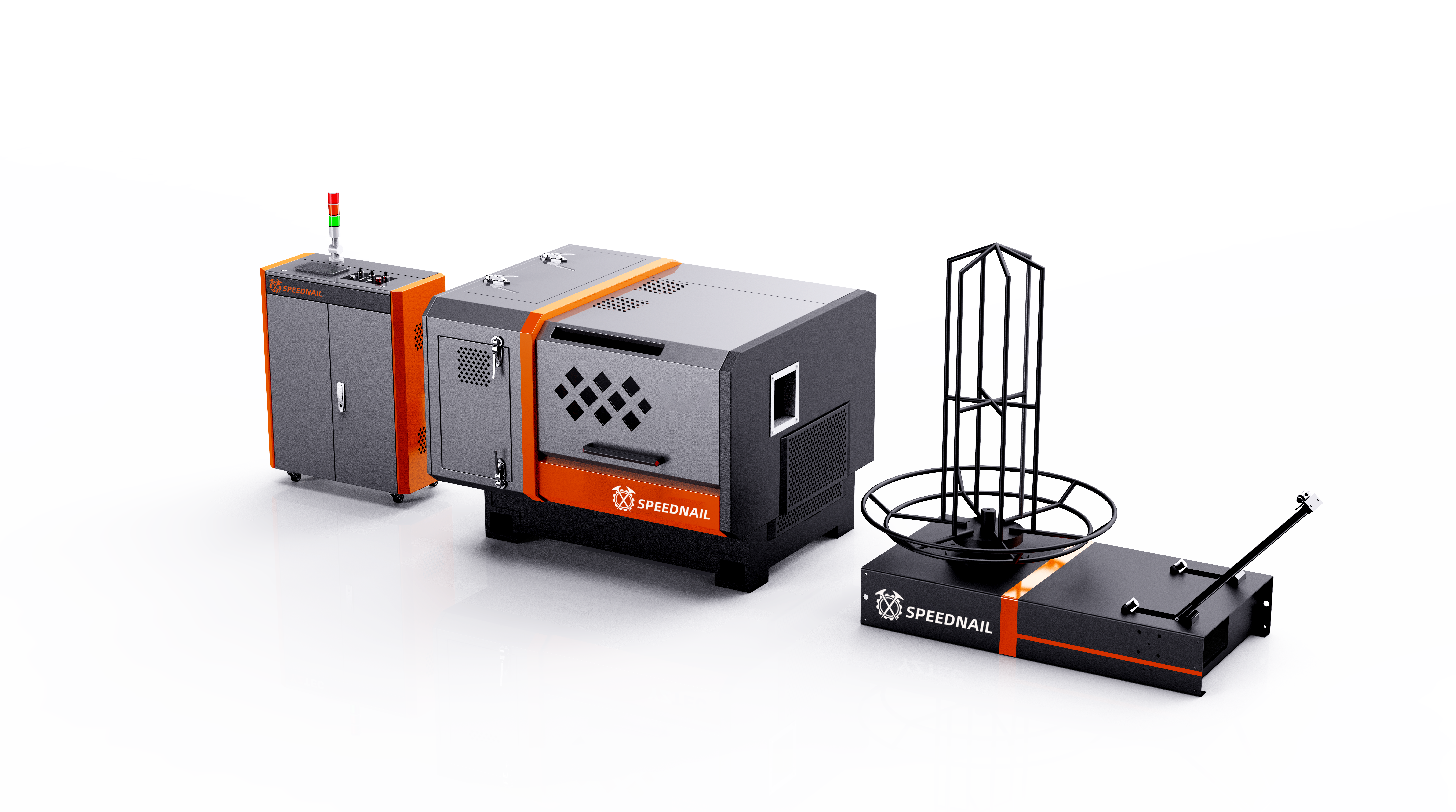

The YZDQ-D100 High-Speed Nail Making Machine is a high-efficiency, energy-saving nail production equipment developed and manufactured by SPEEDNAIL. This automated production machine incorporates advanced mechatronics technology and is specifically designed for large-scale, high-volume manufacturing of metal nails, primarily used for producing high-quality pneumatic nails, cement nails, collated paper strip nails, and common wire nails. It is particularly suitable for processing coil nails with small wire diameters, large heads, and high precision requirements that are currently in demand in the market. Through its precision molds and servo control system, the equipment can rapidly process metal wire into various specifications of standard and special-shaped nails, making it widely applicable in construction, furniture, packaging and other industries.